Quality Management System

Globalization

Integrated Production System Enables Strict Quality Management

Quality Assurance System

Asahi Intecc’s quality policy is to develop and stably supply products that consistently exceed the expectations and the needs of the market by establishing the highest levels of reliability and safety and by contributing to medical care around the world. Aiming to become a truly international enterprise, we will secure further global-grade quality by working to increase the quality of our products on a daily basis. The Asahi Intecc Group has established a quality assurance system that applies international standards of quality management such as ISO 13485, and it acquires and maintains various certifications under these frameworks. Moreover, by complying with the stringent laws and regulations on medical devices in the more than 120 countries and regions in which Asahi Intecc’s products are sold, we have built a quality assurance system that ensures the supply of the high-quality products required by our customers.

Integrated Management of Production Locations and Quality Assurance Division

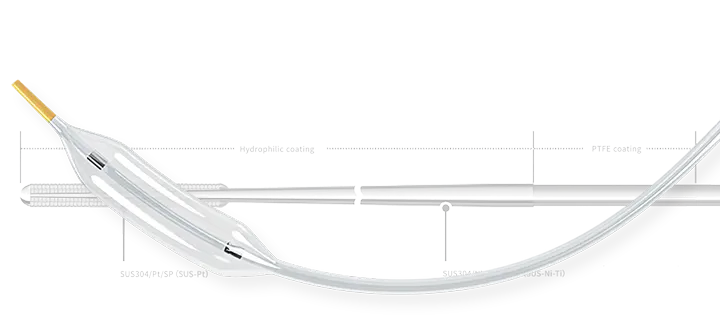

Based on our core technologies, the Asahi Intecc Group has developed an in-house integrated production system that spans from materials to finished products. The materials used in medical devices require highly precise specifications and quality, and the number of raw material manufacturers capable of steadily supplying materials that meet these high standards is limited, even on a global basis.

Therefore, in pursuit of materials that meet our own requirements, Asahi Intecc purchases base materials as far upstream as possible and carries out all subsequent processing in-house to create materials as close to perfect as possible. We also perform all subsequent processes in-house, including packaging and sterilization, and comprehensively manage product quality to deliver high-quality products that are second to none to our customers.

Management System Ensures Advanced Quality Control

Asahi Intecc Group thoroughly ensures that only employees trained based on applicable regulations, standards, and in-house standards whose skills and qualifications have been confirmed are involved in developing, manufacturing, inspecting, and all other works on products for customers. We have established rigorous inspection systems on our production lines, including load testing of products and precise checks on wire bending and lubricity.

Strict quality control and inspections are implemented thoroughly from production through to packaging, with products that have undergone final inspections being shipped to customers worldwide.

Collaborative Structure Maintains Strict Quality Control

Asahi Intecc Group tracks information on quality for all manufacturing processes from raw material manufacturing to final product shipping in a timely fashion. The Quality Assurance Division also collects all customer feedback on quality for survey and analysis.

By conveying this information to senior management as well as manufacturing, research, and design and development locations in a timely manner for use in process and product improvement, we have built a reliable structure for supplying safe and secure products.