Medical Components

Our services

Delivering Minimally Invasive Medical Products from Japan to the World

Improving the quality of life for patients around the world

Asahi Intecc provides customers with high-functioning, high-quality medical and industrial components that make full use of the stainless steel technologies that we have cultivated since the company’s founding. With our integrated production system, all processes from wire drawing to end processing are carried out in-house, which enables us to develop the products that meet our customers’ needs and ensure that these products are extremely reliable.

Medical partsMain Materials Handled

-

Torque coil (multilayer coil)

Our hollow multilayer coil delivers excellent flexibility and outstanding torque performance. Able to maintain excellent torque performance even when bent, the coil also provides high torque, as well. Ideal for intravascular imaging devices and therapeutic catheter shafts.

-

ACT ONE (multi-wire coil)

This hollow wire rope provides superior torque performance, kink and compression resistance, and shape recovery. The coil properties can be customized by changing the shape of the wire and number of strands, making it ideal for steerable sheaths and catheter shafts.

-

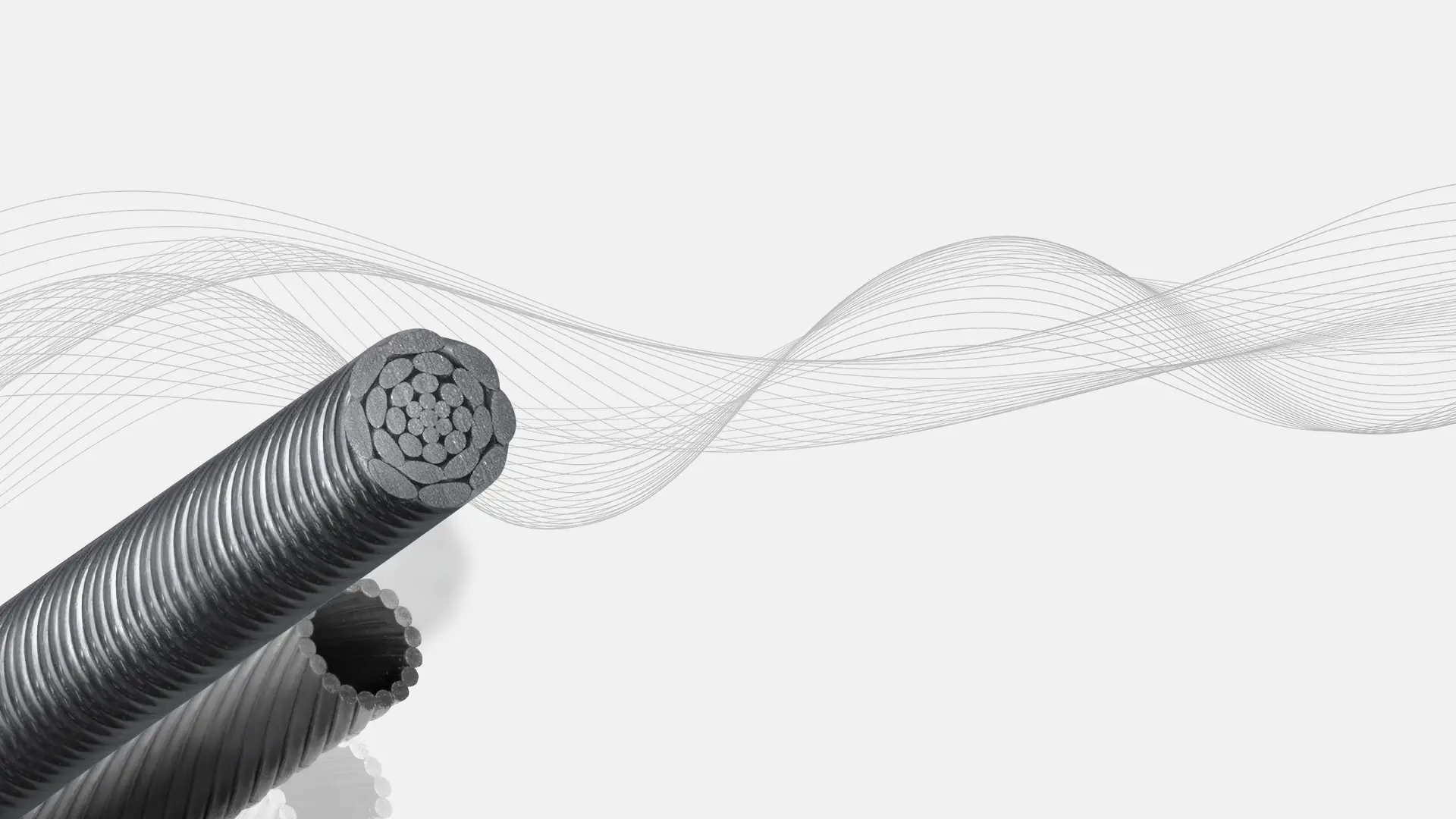

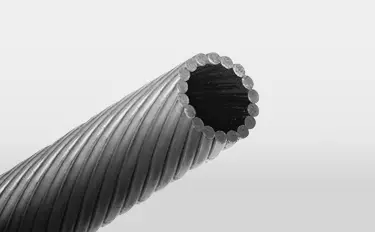

Wire rope

Made with ultrafine wire produced using a wire drawing process, this rope boasts excellent tensile strength and elongation resistance. Ideal for endoscopic wire rope, medical robots, and other products.

-

Outer coatings

With outer coatings, we can add lubricity, friction resistance, durability and chemical resistance to wire ropes and hollow cables. A variety of materials can be coated to suit specific applications.

-

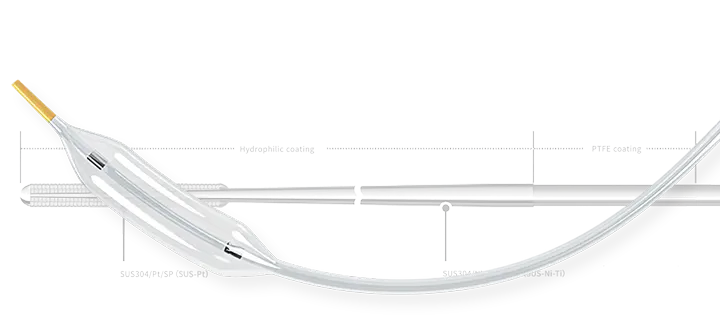

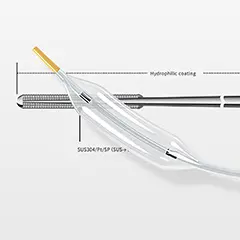

Braid tube

This catheter tubing provides a well-balanced combination of excellent vascular tracking, smooth delivery, and easy insertion. By automating the processing, we are able to deliver high-precision products with reduced lot-to-lot variation for outstanding production efficiency.

-

Special processing/options

Components can be assembled by machining or laser welding.

Surface treatments can also be applied for additional mechanical properties, as well.

ASAHI TECHNOLOGY

Medical and industrial components that utilize our four core technologies and other proprietary material processing technologies bear the ASAHI TECHNOLOGY logo mark as proof of their safety and reliability. This logo on the packaging of our customers’ final products testifies to the use of high-quality materials and gives end users greater confidence that these products are reliable.

Providing high-functioning, high-quality products

Product Details

For more details, including product features, materials and specifications, please refer to Product Information section.