Production System

Globalization

Mass Production at Overseas Locations

Mutually Complementary System Ensures Timely Supply Worldwide

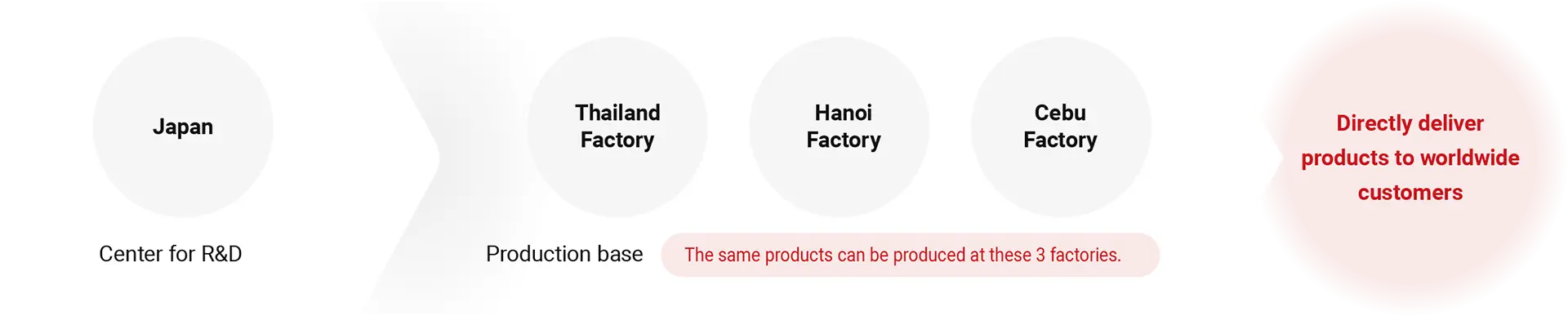

In order to meet customer needs with precision, Asahi Intecc combines powerful R&D capabilities with advanced mass production technologies by integrating R&D and production technology. To establish a production system that serves this role, we employ integrated production from materials to finished products in our factories outside Japan (ASAHI INTECC THAILAND CO., LTD. (Thailand factory), ASAHI INTECC HANOI CO., LTD. (Hanoi factory), and TOYOFLEX CEBU CORPORATION (Cebu factory)).

Main Production Bases

ASAHI INTECC THAILAND CO., LTD.

ASAHI INTECC HANOI CO.,LTD.

TOYOFLEX CEBU CORPORATION

Strengthening Production Infrastructure and Technical Capabilities

Extending and decentralizing production capacity using integrated production, from materials to finished products

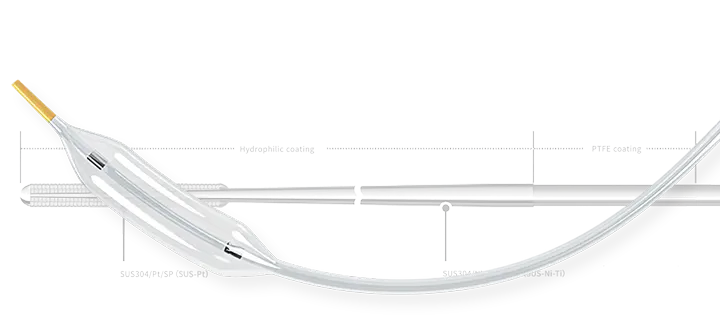

In order to raise productivity with a focus on expanding production of guide wires, our main product, we have made numerous improvements (including the introduction of equipment, machinery, and jigs and the streamlining of operations) to expand our mass production system.

In addition, from the perspective of risk management and the business continuity plan (BCP), we are working to optimize production bases across the Group by establishing a system that enables all three factories to manufacture the same products so that even if one or more factories goes out of operation due to local factors or other reasons, another one can cover the majority of the lost production.

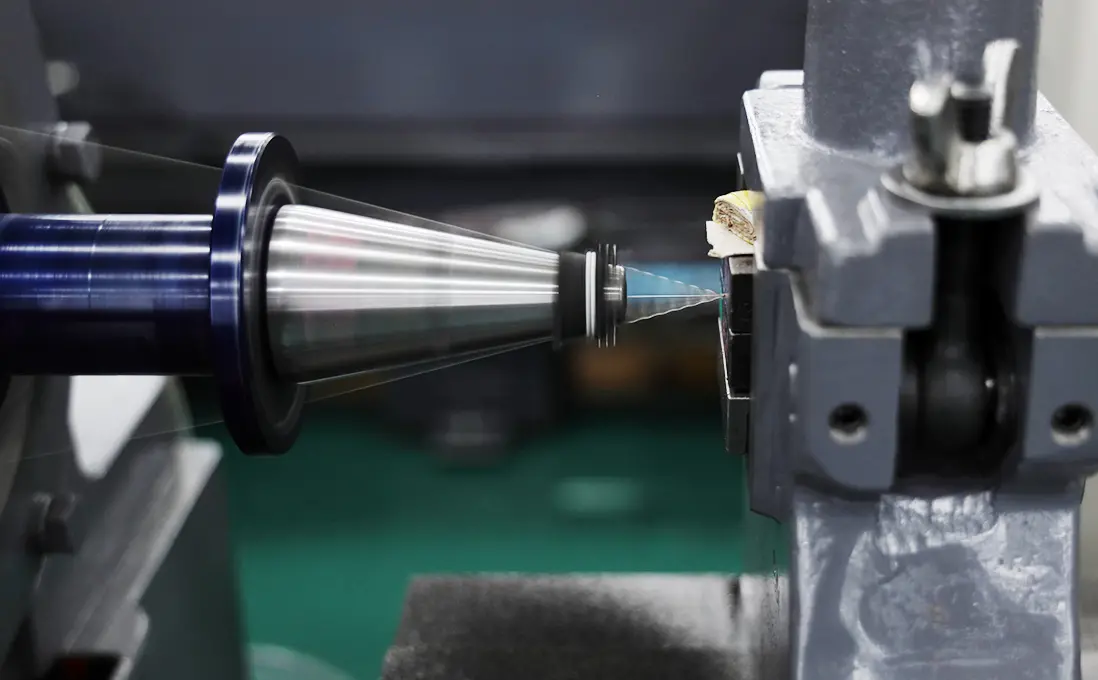

Mechanization, labor force reduction, automation, and leveraging IoT in mass production factories

We continue to promote mechanization, labor force reduction, and automation in our mass production factories to further improve productivity and stabilize product quality. These activities are led by the engineers at each factory based on the expertise accumulated there.

The technical information learned from these activities is shared among bases (Thailand factory, Hanoi factory, Cebu factory, and Japan) to collaboratively strengthen and improve our technical expertise. We also carry out technical studies on an ongoing basis to respond to IoT, and we are implementing initiatives to introduce these technologies into our mass production factories in stages.