Four Core Technologies

Technology

ASAHI TECHNOLOGY

Number-One Products That Consistently Deliver Safety and Reliability

Source of Asahi Intecc Group competitiveness

Integrating four core technologies to create solutions for sophisticated needs

As an R&D-oriented company, we ensure that Asahi Intecc products are manufactured to extremely high standards.

To do this, we leverage numerous proprietary technologies we have developed in the process of meeting our customers’ sophisticated needs.

We draw on our proprietary core technologies in the areas of wire drawing, wire forming, torque technology, and resin coating, integrating these in sophisticated ways to create high-performance products.

Wire treatment

Wire drawing technology

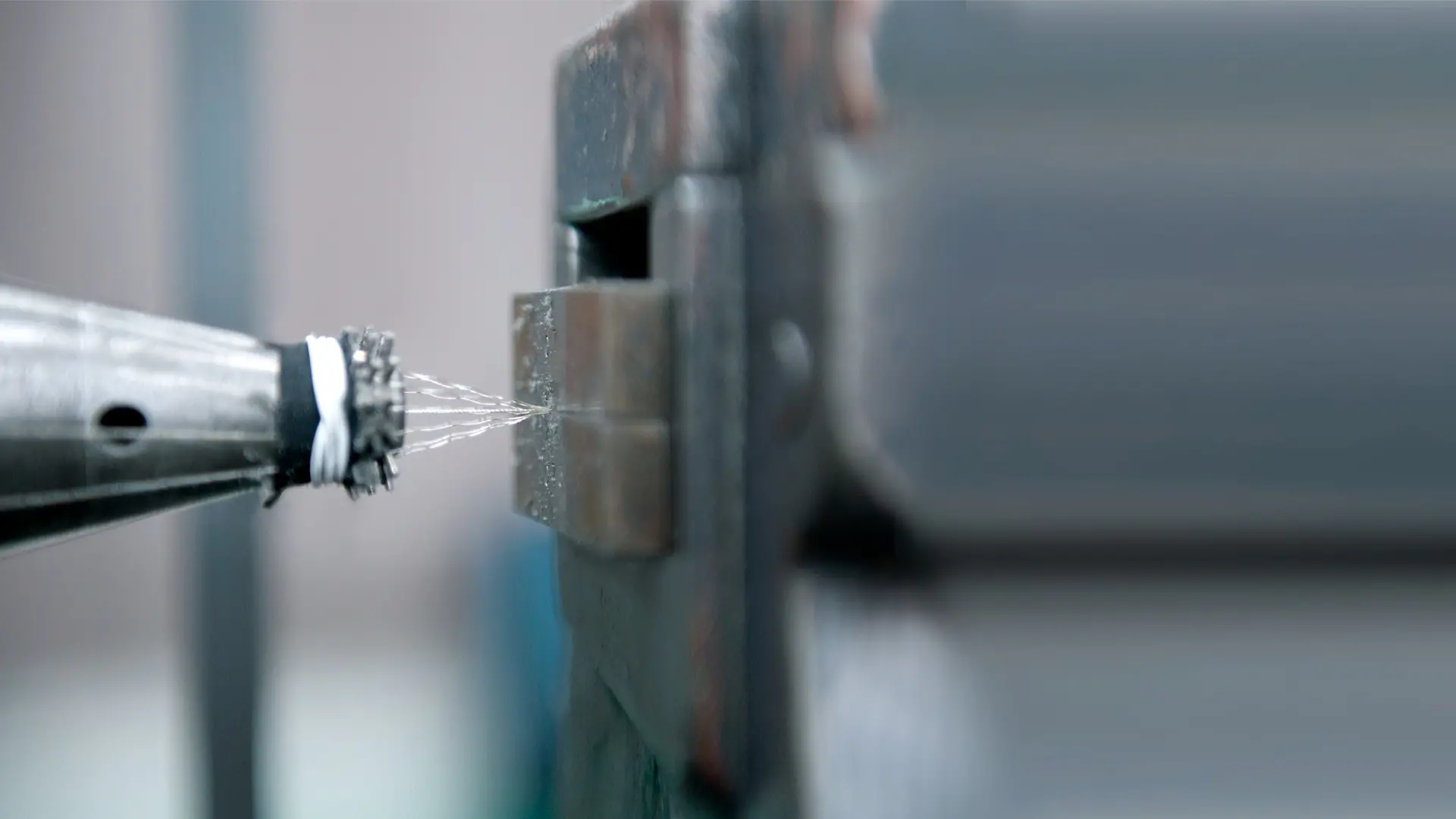

Asahi Intecc applies its high-precision wire drawing technology to manufacture the wires used in PCI guidewires and the braid wire embedded in guiding catheters for procedures.

The centerpiece of this wire drawing technology is called “dice,” and it is about 2.5 cm in diameter with micron-level holes at the center.

The holes in the dice are surfaced with hard diamonds, but they still gradually wear away with use. In order to maintain a high level of precision in the shape of the dice, Asahi Intecc has introduced a high-precision system that inspects the dice shape, measuring and controlling the shape of the holes at the center of the dice to within a few thousandths of a millimeter.

The wire drawing process is elemental to all of our products, and by rigorously controlling this process, we minimize error and produce high-precision components for medical devices.

Wire forming

Wire forming technology

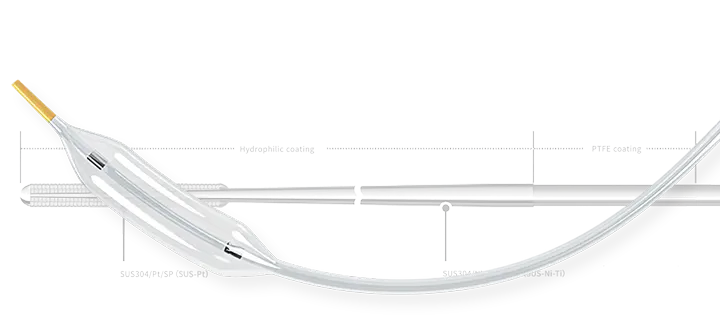

PCI guidewires are designed with a flexible coil structure at the tip to prevent damage to blood vessels. It is Asahi Intecc wire forming technology that is used to manufacture these coils.

In addition to coiling, wire formed into various other shapes at the micron level are used in such products as guiding catheters, angiographic catheters, and wire braids used in microcatheters. (Wires measuring 30-60 µm in diameter are woven and embedded inside the catheter resin tubing to improve catheter strength and operability.)

Torque

Torque technology

Asahi Intecc medical devices are singled out by the market for their outstanding torque performance.

It is our proprietary processing equipment and special torque technology that enables the wire we produce to deliver this ideal torque response.

The outstanding and unrivalled torque performance that we deliver provides sophisticated controllability for guidewires, catheters, and other medical devices.

Coating

Resin coating technology

Different types of coating are applied to medical devices to ensure greater lubricity within blood vessels.

Asahi Intecc’s ultra-thin film coating technology provides micron-level control of hydrophilic polymers, silicone, PTFE, and other elements, bringing even more advantages to the medical devices that benefit from it.